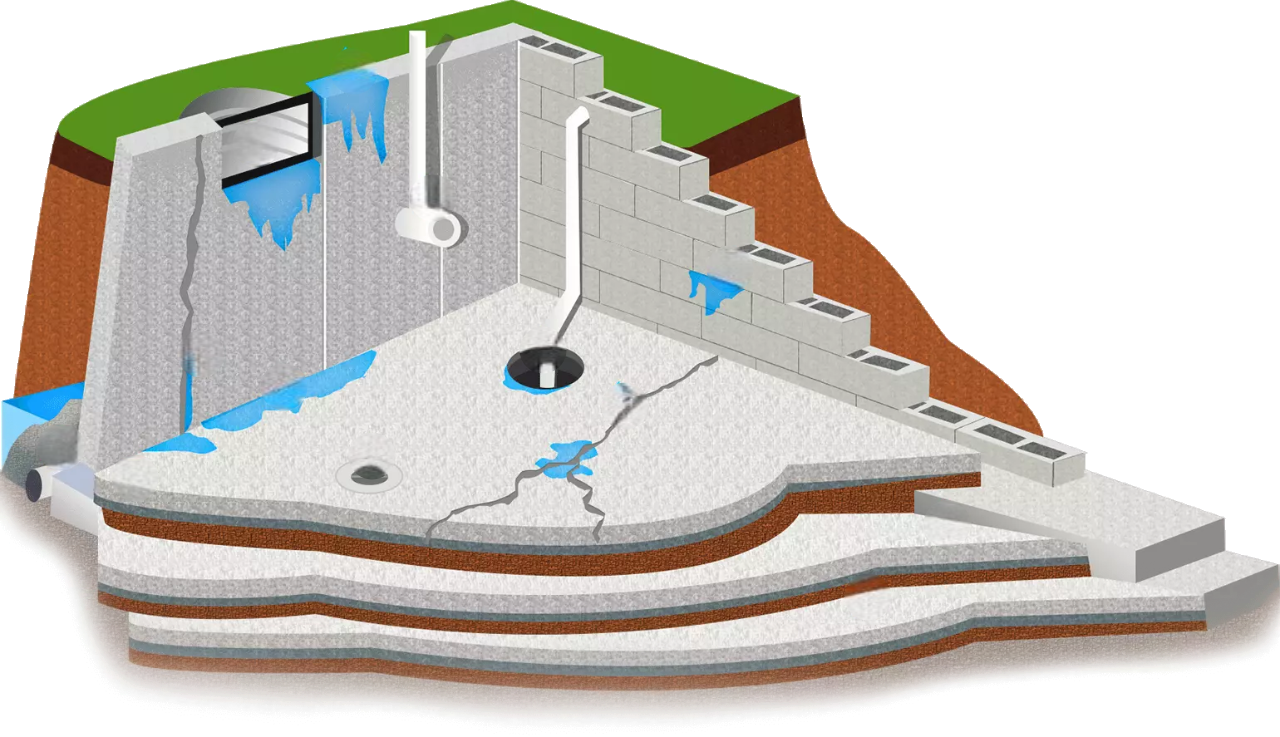

We don’t simply just provide a waterproofing price; rather, we take the time to understand your home and why your foundation is leaking. All our projects follow an established step-by-step process to ensure homeowners have confidence and long-term results.

The Do’s and Don’ts of Interior Waterproofing

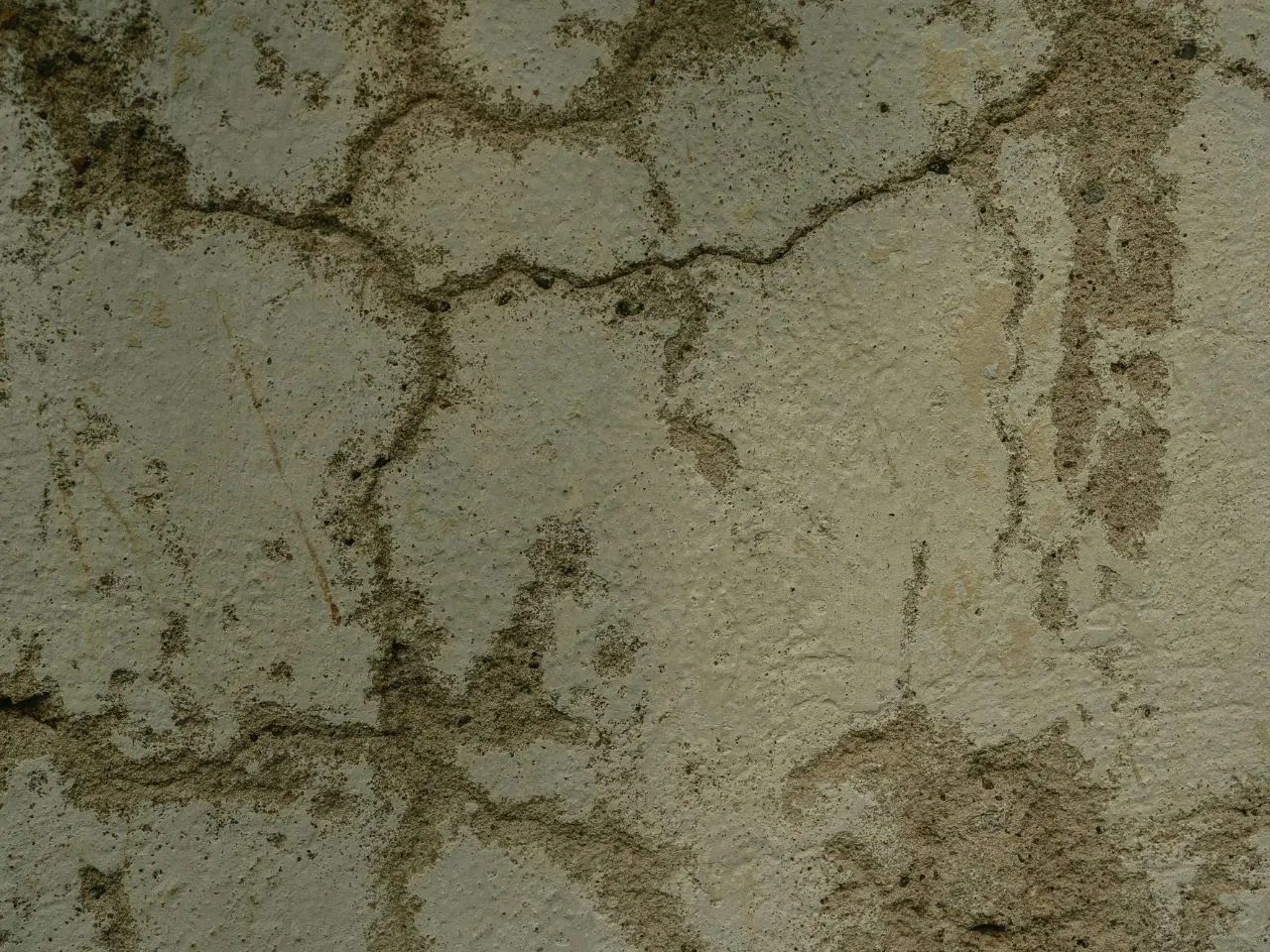

The Do’s and Don’ts of Interior WaterproofingIt becomes imperative to waterproof your house for longevity and healthy integrity. Without interior waterproofing, the structure may give up – thanks to water and foundation leakage.